Bambu Lab Double Sided 257MM*257MM Spring Steel Sheet

7,000.00 ₨

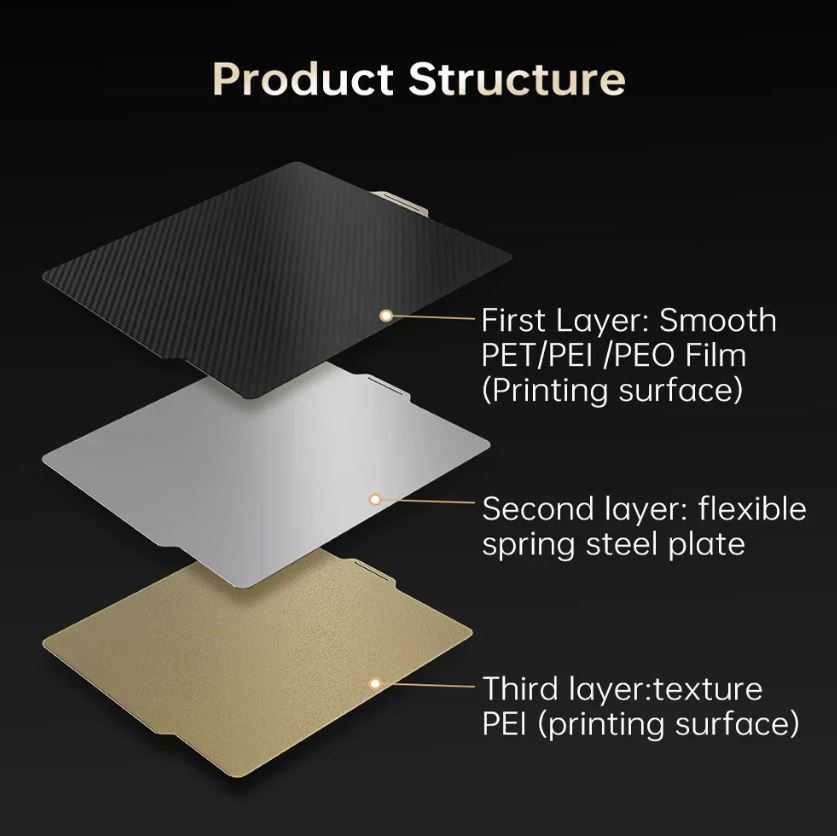

Steel Sheet For Bambu Lab, The BIGTREETECH Double-Sided spring steel sheet features three layers, combining a central spring steel core with surrounding materials seamlessly fused for optimal performance.

What’s the difference between PEI, PEO, and PET build plates in Steel Sheet For Bambu Lab?

- PEI surface.

Characteristics: PEI is a high-performance, heat-resistant polymer that is widely recognized for its excellent mechanical properties and resistance to chemicals. Moreover, it has a smooth surface that promotes good adhesion and is frequently used as a build surface for a variety of filaments.

Common Use: In fact, PEI is commonly used for printing materials like PLA, PLA-CF, PETG, PC, ABS, TPU, Nylon, and more. As a result, it has become a popular choice for various types of 3D printing projects.PEO surface.

Characteristics: PEO is a water-soluble polymer, primarily known for its ability to dissolve in water. Consequently, this feature makes it suitable as a support material, which can be easily removed by immersing the printed object in water.

Common Use: Typically, PEO is often used as a support material for dual extrusion 3D printing. Once printing is complete, it dissolves in water, leaving the primary printed material intact. However, it is not typically used as the main build plate material in Steel Sheet For Bambu Lab.PET surface.

PET (Polyethylene Terephthalate):

Characteristics: PET is a common thermoplastic polymer known for its transparency, strength, and flexibility. In particular, in the context of 3D printing, it is often used as a base material for build surfaces or as a film adhered to build plates.

Common Use: PET is used for its smooth surface and good adhesion properties. Additionally, it is commonly found as a thin film on build plates to provide a suitable surface for 3D printing. Therefore, PET has become a reliable option for many 3D printing applications.

Key Features:

- High Usage and Reusability. With nearly 1000 successful prints, our build plate consistently maintains colorful and intricate patterns while also offering a remarkably high reuse rate.

Furthermore, the excellent first printing layer adhesion provided by the build plate eliminates the need for glue, thus making printing easy, even for beginners.

In terms of maintenance, you can easily keep the surface clean by wiping it with a wet tissue and drying it with a dry tissue – there’s no need for alcohol or other cleaning solvents.

Additionally, model removal is made simple. The spring steel sheet allows quick and tool-free removal of models, as the plate returns to its flat state without any deformation.

Moreover, you can benefit from the double-sided printing capability of the spring steel sheet, which maximizes its utility.

The sheet is constructed of high-quality stainless steel, so it retains its flatness no matter how much you bend it.

Finally, the flat and flexible nature of the spring steel sheet makes installation a breeze – you simply put it on and start printing. - Steel Sheet For Bambu Lab

Usage Guidelines:

1. Ensure proper leveling for the first print (A4 paper thickness between the nozzle and hotbed).

2. Apply the magnetic sticker to the hot bed platform, ensuring it’s flat without air bubbles.

3. Affix the PEI or PEO side spring steel plate to the magnetic base (remove PEO film before use).

4. Start printing, adjusting the heating bed temperature as needed.

5. After printing, gently bend the plate when at room temperature for easy demolding.

| Options | 257MM*257MM PEI + PEO, 257MM*257MM PEI + PET, Textured PEI x Textured PEI |

|---|

Related products

CNC & 3D Printer Parts

10mm Screw Rod M10 Threaded Rod For CNC Machine And 3D Printer

CNC & 3D Printer Parts

CNC & 3D Printer Parts

LPT Printer DB25 M F Cable & MACH3 DB25 Parallel Cable in Pakistan

CNC & 3D Printer Parts

CNC & 3D Printer Parts

1-7mm ER11 Spring Chuck Collet Set With Clamping Hex Nut For CNC Milling Lathe Engraving Machine

CNC & 3D Printer Parts

CNC & 3D Printer Parts