Bambu Lab High Temperature Plate (Smooth PEI)

24,000.00 ₨

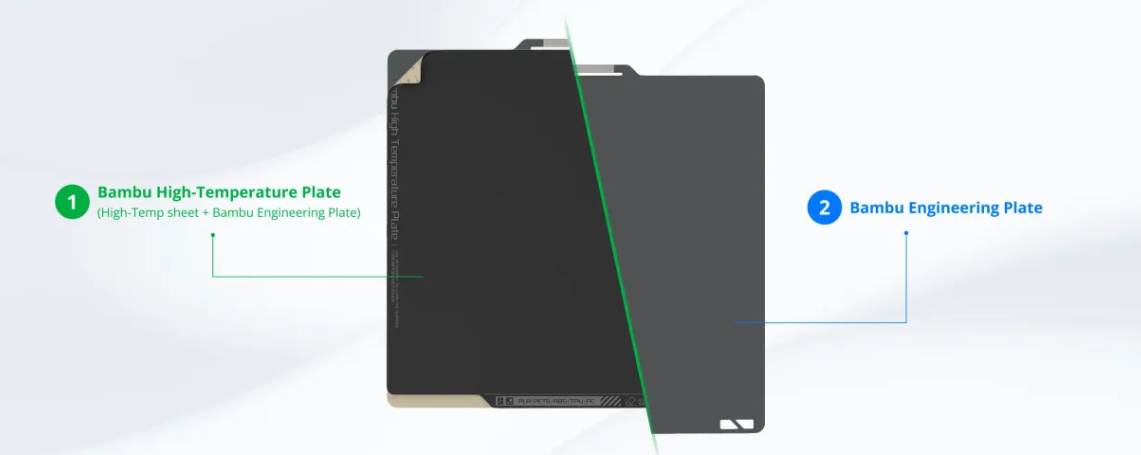

One side: Bambu High Temperature Plate = High-Temp sheet + Bambu Engineering Plate

The other side: Bambu Engineering Plate

1.Bambu High-Temperature Plate

Please note that other slicer settings might need to be adjusted based on the printed model and the filament requirements

| Material | Heatbed Temperature | Glue Stick Required? | Upper Glass Cover Plate Removed? |

| PLA/PLA-CF/PLA-GF | 45~65℃ | No | Yes |

| PETG/PETG-CF | 60~80℃ | Yes | No |

| ABS | 90~100℃ | Recommended | No |

| ASA | 90~100℃ | Recommended | No |

| TPU | 35~45℃ | Recommended | Yes |

| PVA | 45~60℃ | Recommended | Yes |

| PC/PC-CF | 100~110℃ | Yes | No |

| PA/PA-CF/PAHT-CF | 100~110℃ | Yes | No |

| PET-CF | 80~100℃ | Yes | No |

Benefits

Works best with most 3D printing filaments

Works well with the Automatic Calibration for Flow rate and does not interfere with the LIDAR

Smooth texture on the surface of the print

Excellent adhesion and easy print removal

Can be replaced by the user

Downsides

It cannot be used without heating the printing surface

Can be more fragile compared to the Engineering Plate or Textured PEI Plate

The upper glass cover plate, or the front glass door need to be opened for filaments with a low glass transition temperature

2. Bambu Engineering Plate

Please note that other slicer settings might need to be adjusted based on the printed model and the filament requirements

| Material | Heatbed Temperature | Glue Stick Required? | Upper Glass Cover Plate Removed? |

| TPU | 30~35℃ | Recommended | No |

| PETG/PETF-CF | 70~80℃ | Recommended | Yes |

| PET-CF | 70~80℃ | Recommended | Yes |

| ABS | 100~110℃ | Yes | No |

| PC/PC-CF | 100~110℃ | Yes | No |

| PA/PA-CF/PATH-CF | 100~110℃ | Yes | No |

Installation Steps

Step 1: Align the plate with the fixed points of the platform with the name of the plate facing you

Step 2: Lower the plate and secure to the magnetic platform

Product Specification

| Material | Smooth PEI sheet + Spring steel + Engineering Coating |

| Surface temperature resistance | Up to 120℃ |

| Flexible spring steel thickness | 0.4 mm |

| High-temp Plate sticker thickness | 0.03 mm |

| Usable print size | 256*256 mm |

| Package size | 290*290*4 mm |

| Package weight | 450 g |

| Color | Black |

Considerations

- Variations in the color and luster of the Engineering Plate appearance and the removal of the exposed metal areas are just minor adjustments to optimize the production process and surface quality. If the coating remains on the nozzle when the nozzle is wiped, it will be heated and melted before printing the model. Such changes do not affect leveling, Lidar, adhesion, or range of use. You can purchase with confidence!

- Before auto-leveling, it is necessary to repeatedly rub the nozzle in the special wiping area of the build plate to completely remove any residual material at the tip of the nozzle. The coating in the special-designed wiping area will gradually become worn over time. This is normal and does not affect print quality or nozzle lifetime, so there is no need to worry about any quality issues.

- Bambu Lab recommends only using Bambu Lab official glue on the build plate, and can not be held responsible for any damage caused to plates as a result of using third-party glue on build plates.

- Regularly clean the print surface with dish soap and hot water to eliminate any dust or grease residue, which might cause bad adhesion. IPA can also work, but the best solution to clean the plate is washing it, to ensure the best performance.

- Always wait for a few minutes before removing printed models to allow the plate to cool down for easy print removal. This prevents damage to the plate and ensures a long lifetime of the product.

- The High-temp smooth PEI plate is considered a consumable part, which will degrade over time. The warranty will only cover manufacturing defects, not cosmetic damage like scratches, dents, or cracks. Defective sheets upon arrival are the only ones covered by the warranty.

Related products

3D Printers Accessories

3D Printer Silicone Cover Creality Accessories Silicone Sock Heating Insulation Case

3D Printers Accessories

3D Printers Accessories

3D Printers Accessories

Original Creality Assembled Extruder Hotend Kit with 0.4mm Nozzle Aluminum Heating Block